Buy-Online-Pickup-Later

Launching a New Fulfillment Method at Dick’s Sporting Goods

How did we deliver over $35 million in incremental sales over the last 2 years? OverviewDick’s Sporting Goods needed a way to unlock inventory from their Distribution Centers.

Pickup order cancellations were rampant, inventory on high-demand items was stretched, and customers demanded more.

BOPL (Buy-Online-Pickup-Later) was implemented to give customers options, and to increase sales.

RoleSenior Product Designer /

Store Technology Representative

Product Strategy, User Research,

Visual design, Pitching,

Prototyping and Testing, Facilitation

2022 Strategic Initiative

“Know what your customers want most and what your company does best. Focus on where those two meet.”

Background

Customer demand for exercise and outdoor equipment was at an all-time high in 2022.

Products deemed ‘big and bulky’, items like treadmills and exercise bikes were difficult to keep in stock in the stores. Each store only carried one display item and one or two backstocks. With the high demand, pickup orders were being placed for inventory that was walking out the door.

Customers were upset. Sales were being missed. A core team was identified across e-commerce, supply chain logistics, store technology, and store operations to determine the best solution to this problem. The solution became an entirely new fulfillment method: Buy-Online-Pickup-Later aka BOPL.

BOPL saw over $12 million in sales in its first year.

I was the lead designer on the in-store fulfillment team. I also acted as the representative for Store Technology within the core committee of 6 individuals tasked with leading efforts to launch BOPL. On my product team, we had two product designers, 1 business analyst, and 4 engineers.

I was responsible for coordinating the end-to-end product journey from the point the order was taken by e-commerce, to the handoff to our customer. This journey touched our customers, our DC teams, the store fulfillment team, and our in-store employees.

Implementing BOPL took nearly six months from the early stages to begin its initial rollout. Our goal was to meet the business deadline and launch by the Holiday Season in 2022. BOPL was launched shortly after Cyber Monday, for all 800+ stores. For me, some key achievements were:

Working with a large, cross-functional team. My role as facilitator and the sole designer on the core committee led me to take point on the discovery process. We conducted user interviews with all three major user groups: customers, in-store employees, DC employees, as well as our business partners.

Executed end to end. We delivered a final product that was seamless from the customer order process to the final handoff in-store. Nearly 60 touchpoints and over 15 product teams were involved.

Delivered Business Value on time. Working with a large team, we were able to deliver BOPL to our entier customer base by the deadline for Holiday 2022 and to deliver an increase in nearly 2 million unexpected sales during the season.

Understanding the Problem

This was a unique project for me in my career up to this point.

Throughout implementing BOPL, my role as an individual contributor and my role on the committee led me down similar, but at times very different paths. I was essentially working on the problem at the macro and micro level at the same time.

From my team’s perspective, we had two major problems to solve:

As an in-store employee, I need a way to know when a BOPL order is heading to my store and when it has arrived.

As an in-store employee, I need the ability to work a BOPL order (pick and pack) and make it as ready, so that the customer will know it is available to pickup. Once the customer arrived, we needed a way to leverage our existing pickup flow as well.

For the overall project, I needed to identify the ideal end-to-end flow and discover opportunity points for teams to work on their respective expertise. We were able to break the problem into 3 major bodies of work:

Customer Order / Pickup

DC Logistics — Pick/Pack and Ship

In-Store Experience — Receive, Pick/Pack and Deliver the order

Identifying a top-level problem was simple: As a customer, I need the ability to order and pick up a BOPL order.

Executing it would be much more complex.

Discovering the Ideal Journey

The core committee quickly identified the basic stages of the journey. We broke into teams and did contextual inquiry for each of the areas identified. I led the discovery for the DC Logistics teams and the in-store experience.

We visited all four of our DCs over the next month. Our goal was to understand their current processes for loading a truck (delivering to a DSG store) and to see how the DCs optimized working e-commerce orders.

Some key insights from the DC teams influenced our final process:

Insights • The DC teams work fast. They needed a visual indication to catch their eye from multiple perspectives.

• The DC manifest is not perfect. Stores needed a way to validate the customer order being delivered was in fact on that particular truck.

• They leveraged staging items effectively: every item was scanned into the location it was placed. We would use this process to update the order status in future iterations for our customers’ benefit.

Research Methods (flip to horizontal categories)Contextual Inquiry, Discovery Interviews, Process Mapping, Stakeholder Interviews, Ideation

In-Store Employee Experience

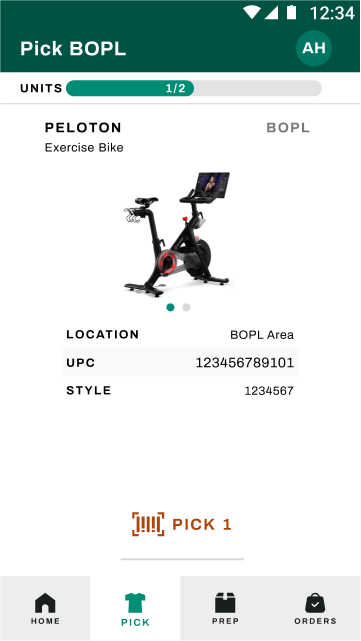

Stage One: Pick

After the order is received at the store, an employee must verify the order is correct by scanning the UPC.

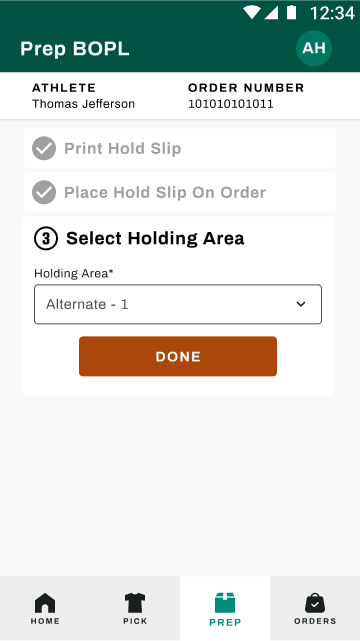

Stage Two: Pack

Prepping the order for pickup sends an alert to the customer that their order is Ready for Pickup.

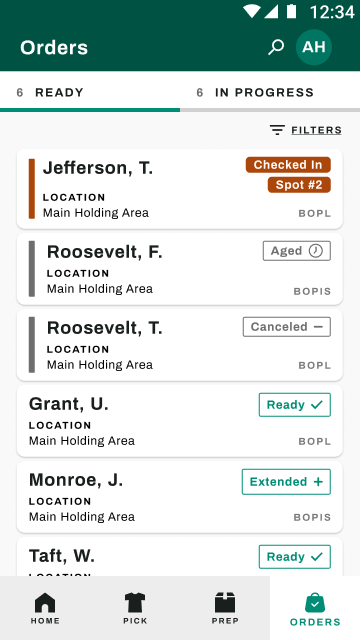

Stage Three: Pickup

Once the customer arrives, an alert is triggered in-store. The employee then carries the order out to the customer.